Frac sand hauling is really booming!

Here’s how it works: A frac sand bin is filled at a terminal or a rail-to-truck facility. Then a chassis or dropdeck trailer with twist locks hauls the sand to an oil well pad where a forklift removes the bin. Empty containers are returned as you get another load. This is a high volume enterprise and a really tough work environment.

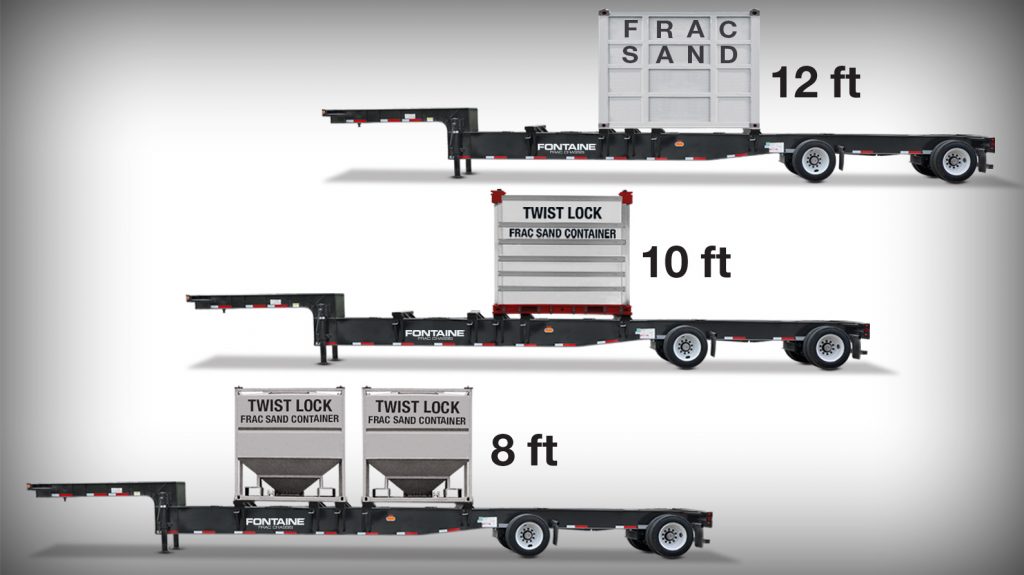

Fontaine Frac Bin Chassis Haul 8ft, 10ft, or 12ft bins with ease.

The Fontaine Frac Chassis is set up to give you maximum versatility. Twist locks are positioned to accommodate the most popular bin sizes.

Fontaine Frac Bin Chassis

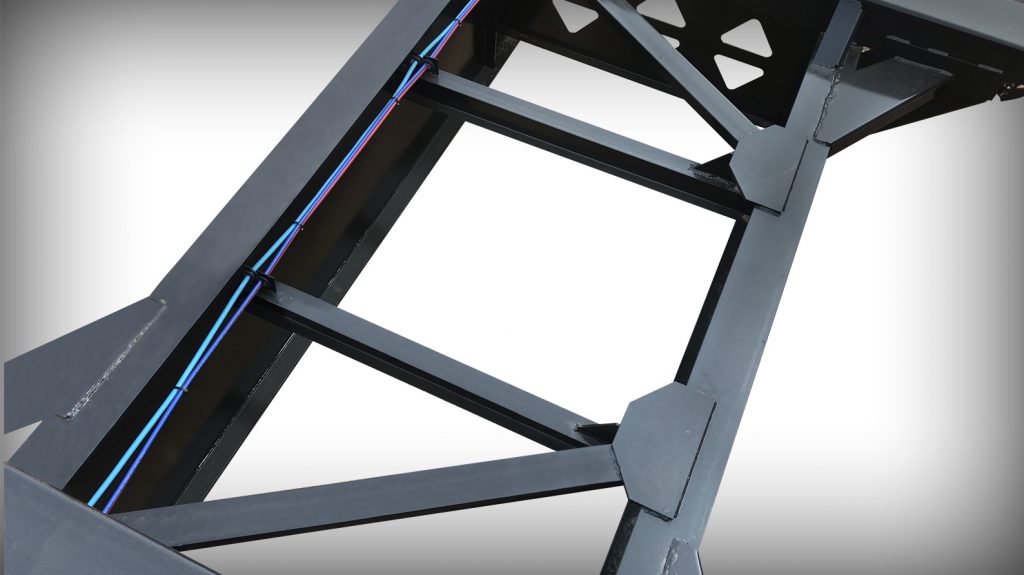

Steel reinforced for greater durability.

Steel reinforced bolsters handle the punishing conditions of this tough application.

Fontaine Frac Bin Chassis

Built stronger to last longer.

Steel reinforced mainbeams are made to withstand heavy loads in the oil field environment. Wiring harness is neatly tucked away and protected by the mainbeam flange.

Fontaine Velocity TX dropdeck

Versatility in steel.

This all-steel workhorse handles typical dropdeck loads PLUS it is set up with twist locks to engage frac sand bins. Now you can haul frac sand or conventional dropdeck loads with the same trailer.